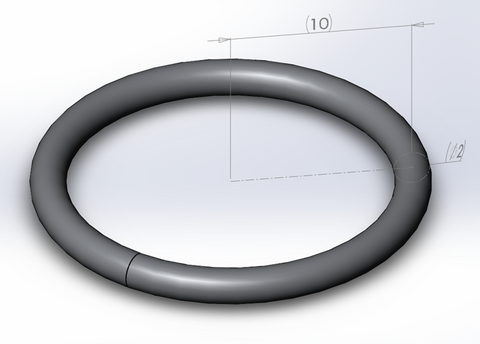

BRAZING RINGS

Your application may require brazing rings because of your parts shape. Usually, we are talking round tube pieces and this is very common in the heating exchanger HVAC, refrigeration industry as well as in the pneumatic, hydraulic fittings industry but it also extends to any application in the automotive, aeronautic,

medical, pharmaceutical industries...

We are able to manufacture very flat rings within a tolerance of ± 0,1mm and with a very precise butt closure. You will take advantage of their spring effect to tighten them thanks to our annealing process.

We have the flexibility to provide rings samples usually of 500-1000 rings to run a pre-series trial as well as thousands of rings for your series production within a short lead time.

You would just have to give us the ID ( inner diameter) of your ring and well as its wire section and we would quote you such.

You also want to keep control of the brazing consumable quantity you are going to use over the time and not being dependant of the human factor as a matter of costs control and stability process control. This totally makes sense in a high production series. With a software we did create, we will be able to pull data, calculate your rings weight and help you quantifying so that you control your costs and consumable needs on a regular basis.

The rings placement and brazing process can also be semi-automated or automated then.

Watch our video of U-bend type heat exchanger with rings manually placed and our 15Kw HF generator using an inductor mounted on an automatic robot arm and programmed to the exchanger pattern matric.

We can also help you getting trough a full generator installation until the implementation and operator training on your shop floor passing by establishing the right brazing alloy with the right ring's dimensions.

Feel free to contact us CONTACT US – DISPENTECH